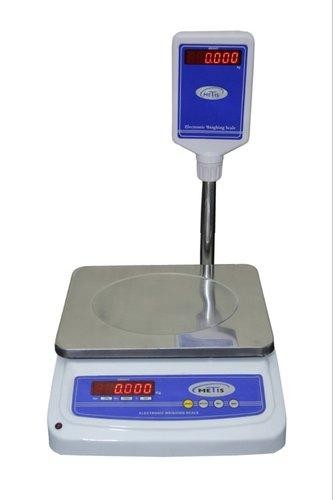

Weight plays a crucial role in most industrial environments. Many blending, mixing, and formulating processes, sales, shipping and receiving, and many more are dependent on weight. Earlier, the weighing scales used were manual, but digital platform scales have come on board with time. These digital platform scales are equipped with electronic intelligence, LCD screens, and accurate load cells. Digital platform cells are designed to determine the weight of all the objects that may be placed on them.

In addition, these digital scales can weigh objects up to 20,00 pounds. The mechanical scales have their pros as they are completely electricity-free, whereas digital weighing scales are not. However, digital scales make that application possible that manual weighing scales do not allow. In this article, we will understand why accuracy is better on digital platform scales.

Digital Scales have a display Screen.

Analog platform scales have a sharp needle that points to the weight. Therefore, you have to read the weight, which results in high chances of human error. However, digital platform scales have an LCD screen display where the weight is directly displayed on the screen, and you read it from there. Thus, it nullifies the chances of human error. This is one of the primary reasons why digital scales have proven to have better accuracy. In addition, the digital screens display weight even to a decimal place, which is not possible on an analog platform scale.

Scale Methodology

Manual scales have inbuilt springs that are used for calculating the weight. However, the digital weighing scales use sensors for calculating the weighing. As a result, the springs in analog scales wear off or loosen after some time, resulting in fluctuation in weight calculation. In contrast, the digital scales do not have any such issues.

Measure Small Objects

Digital weighing scales can be used to weigh even the tiniest of objects which means the sensors sense every little mg placed on them. On the contrary, manual scales do not have such sensing. They only start to measure weight after certain grams are put on them—another reason why digital scales have better accuracy than manual scales.

Advanced technological features

Modern digital weighing systems are equipped with advanced technology such as smart sensors to calculate water weight, BMI, etc. These sensors help in displaying weight by segregating it into different units. They are designed to be light and still can measure weight more than the manual platform scales.

The age does not affect the accuracy of digital scales.

In the worst-case scenario, if your weighing scale has not had an accident like a fall or has been treated badly, there is no reason for the accuracy to be affected. Even when your digital platform scale has gotten older, it will still accurately display the results because it uses smart sensor technology, which only needs power to run and nothing else.

Practical Usage

In digital platform scales, the load of the objects is converted into an electrical signal that is displayed as numbers on the screen. However, on the manual or analog platform scales, you must place the weights against the table to calculate the weight and reach a balance. The manual scale weighing technique may also need re-checking, hence, time-consuming.

Can be configured

Digital scales provide easy configuration as per your requirements. You can configure the weighing scale to the nearest pound of weight that you need to. Additionally, even if you need the weight near to one-tenth of an ounce, the digital platform scales allow you to configure that too. The weight is still accurately displayed.

Final Word

Digital platform scales have set up a huge market for themselves in a short period because of the weight accuracy that they render. Digital scales are not only used in industrial setups but also in hospitals and other industries. This is because they are lightweight but have a high weight measuring capacity.

New advancements in technology have also resulted in equipping the digital platform scales with the latest software. You can link them (wired or wirelessly) to stock or accounting control systems. This excludes the risk of human error while entering the data and also saves time. The latest systems also allow you to store the data and then transfer it via USB or to other storage devices for further usage.