You may be searching for a new air compressor, but the dizzying array of options now on the market makes it difficult for you to choose the model that will serve your business in the most effective manner. Depending on the nature of your work and the environment in which you perform it, a rotary screw compressor can be the most appropriate choice for your business. Suppose you are in the market for gas and air compressors for a medical institution. In that case, you will find a wide selection of sizes and varieties available to fulfill the requirements of your sector.

What Is a Rotary Screw Compressor?

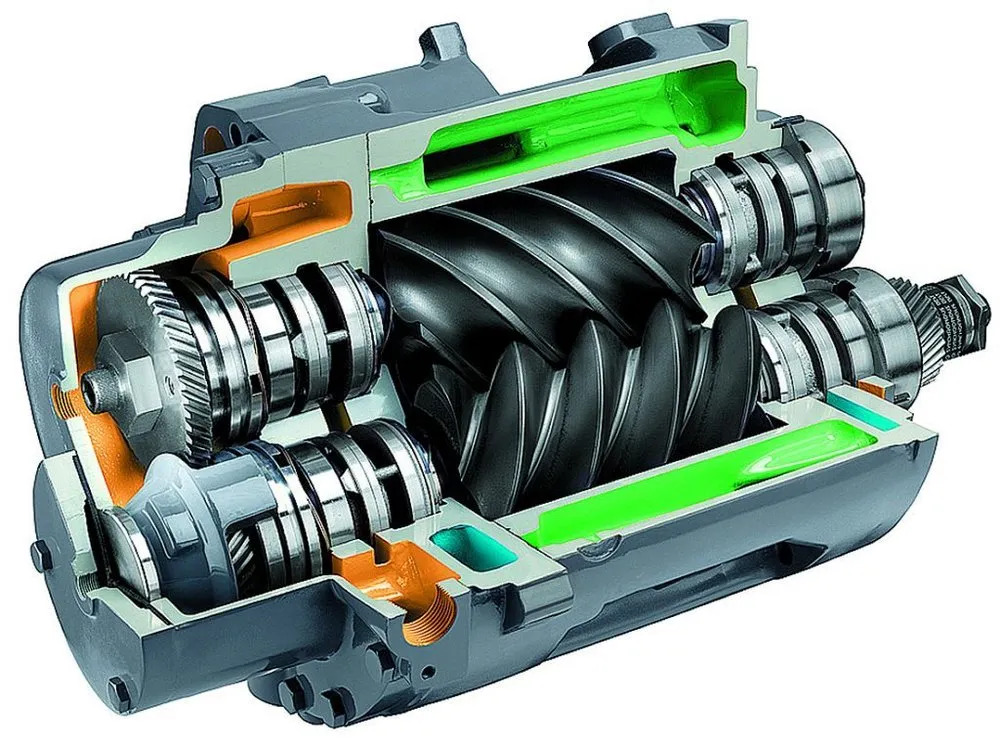

The Rotary Screw Compressor is a type of compressor that uses rotary screws. A rotary screw compressor resembles two enormous screws linked with threads and looks like this: Air is drawn through the compressor as a result of the rotation of the rotors, which are called screws. In general, there are two categories of rotary screw air compressors, and they are as follows:

High pressure is generated using a rotary screw compressor that does not require oil through a process known as two-stage compression. Oil-free compressors are designed for use in settings where any oil present cannot enter the airflow. These compressors find most of their applications in the medical, food, and pharmaceutical manufacturing industries. You can easily find such Compressors Online at the best prices.

This type of air compressor uses a single stage to achieve high pressure; oil is injected into the system to lubricate and cool the rotors. Oil-injected compressors are more cost-effective than their oil-free counterparts and are, therefore, more commonly used in manufacturing and industrial applications.

Compressors With Rotating Screws That Come In a Variety Of Configurations

Let’s take a look at both types of rotary screw compressors, as there are two distinct kinds of these machines.

Compressor That Operates At a Constant Speed

The fixed-speed rotary screw compressor can turn on and off as needed and maintain a constant airflow while running. This type of rotary screw compressor has lower initial and ongoing costs but must be maintained and repaired regularly over its lifetime. Applications requiring a steady demand for air over an extended period are ideal candidates for this product.

Variable Speed Compressor

It is simple to keep the air pressure at a constant level when using a rotary screw compressor with variable speed since this type of compressor makes it easy to adjust the motor speed according to the job’s requirements. When there is a fluctuation in demand for air, there is a corresponding reduction in energy use and expense. Because of its more advanced capabilities, it operates far more silently than its competitors, which operate at a fixed speed. Although its maintenance and repair costs are substantial, the energy-saving function ultimately saves a significant amount of money over time, the exact amount of which is dependent on the application. Several reliable suppliers are offering Compressors Online for industries.

Characteristics Of Rotary Screws

We discuss a few benefits of using a rotary screw compressor compared to other air and gas compressors.

Consistent airflow A rotary screw compressor can provide continuous airflow for an extended period.

Safety: This compressor can function safely even under extreme conditions, exhibiting no signs of overloading or temperature-related breakdowns, including overheating. Because it is more energy-efficient than other types of compressors, the rotary screw compressor seems to have a significantly longer lifespan than that of different compressors. It is also constructed with internal parts resistant to impact, contributing to its already impressively long lifespan.

Energy efficiency: When determining the total cost of owning and operating air and gas compressors over the long term, one of the primary considerations is the cost of the necessary energy. In a fortunate turn of events, the rotary screw compressor comes equipped with cutting-edge automation tools, which enable operators to work more effectively.

Noise: In contrast to certain other kinds of compressors, a rotary screw air compressor has a shallow level of noise during operation and does not make any loud noises.

Conclusion

Operate a medical institution and believe that a rotary screw compressor is the most suitable type for your organization. It would help if you communicated with only well-known air compressor manufacturers before making any financial commitments to get the best Compressors Online.